How to Improve the Quality of Products Produced by Automatic

作者:周周 日期:2019-10-13 09:18 浏览:

In order to strengthen the quality of glue filling, the first step is to unload the glue. After setting the parameters, the glue A is discharged and connected with the storage tool. Then the glue B is discharged and connected with the storage tool. At the same time, the glue A is weighed by an electronic scale. It needs to be tested many times and recorded each time, so that you can see the correctness of the proportion and strengthen the quality of glue filling very correctly. Feasibility.

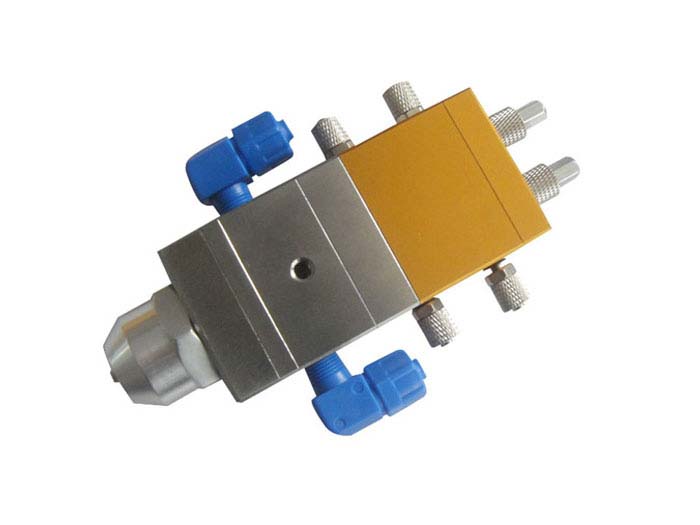

Automatic glue filling and coating machine

The incorrect proportion of glue in the glue dispenser is a very serious problem. If the proportion is not correct, it will lead to incomplete solidification of glue, thus affecting the quality of glue after glue dispensing. This is true for automatic dispenser or high-speed dispenser, etc. Therefore, when the proportion is not a problem, setting the time of glue dispensing for each product to ensure the quantitative glue filling of each product, so that the consistency of glue dosage will help to strengthen the glue irrigation. In order to eliminate the bubbles in the colloid before encapsulating some liquid which is easy to produce bubbles, defoaming, heating, stirring and drying are needed until the bubbles in the colloid are reduced to the minimum value close to zero. In order to enhance the quality of gel filling more effectively, an external vacuum pump is often needed. When the colloid is stored in a stainless steel pressure cylinder, it is pumped by an external vacuum pump to ensure the glue. The bubbles in the body are removed. Before packaging, some colloids need to be heated. In addition, for some colloids with poor solids or fluidity, high viscosity and easy bonding and solidification at room temperature, if necessary, the colloids need to be converted into liquids in the auxiliary heating process to ensure the full flow of colloids in the packaging process.

Guarantee the quality of gum irrigation.

Large flow control glue dispensing machine

The heating process needs to be matched with a set of heating temperature control system. In addition to heat treatment, other colloids which are easy to crystallize when they meet with water in the air also need special production technology to strengthen the filling quality. Among them, polyurethane materials are easy to crystallize, and liquid crystallization not only affects the filling quality of products, but also affects the performance of filling equipment in the packaging process. The way to solve this problem is to use inert gas control to enhance the quality of gelatin.