What glue and equipment is used for PP plastic bonding?

作者:点胶机厂家 日期:2020-07-14 09:41 浏览:

Most of the plastic products in our life are made of PP (polypropylene) as the raw material. There are some differences between the glue used for bonding PP plastics and the way of dispensing. If the equipment is selected, it can be put into production and application through a special standard dispenser, while the glue needs to be used in the production of two-component ratio instant adhesive.

PP board adhesive dispensing

Choose glue

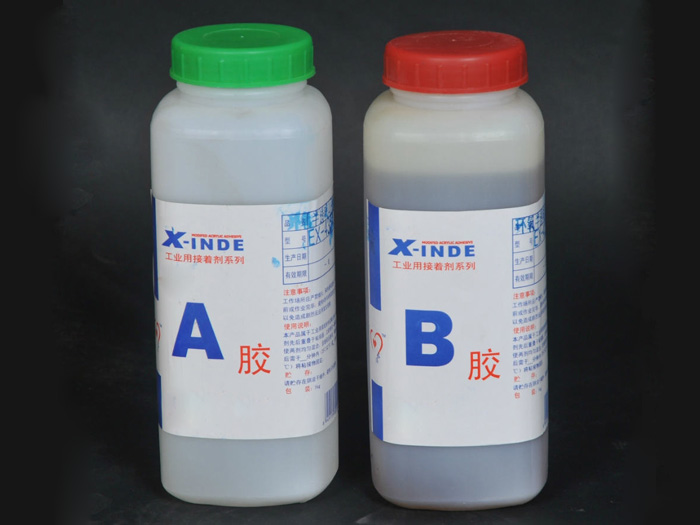

The two-component instant glue with mixing adjustment is suitable for PP plastic bonding. It is a light yellow adhesive fluid with medium viscosity. It can be coated and bonded without treatment of PP plastic. The initial curing strength is achieved in about 5 minutes. Considering that there is a large amount of solvent in the instant glue after mixing, the dispenser needs to wait for several minutes to let the solvent gradually volatilize After that, the materials were bonded. It is necessary to wait for 24 hours to achieve the best fixed strength. After bonding, it can be seen that the tensile strength of PP plastics will be more prominent. If a great pull force is applied, the PP plastic may break, but the bonding position is still not broken, which is the operation advantage of two-component mixing.

Two component curing adhesive

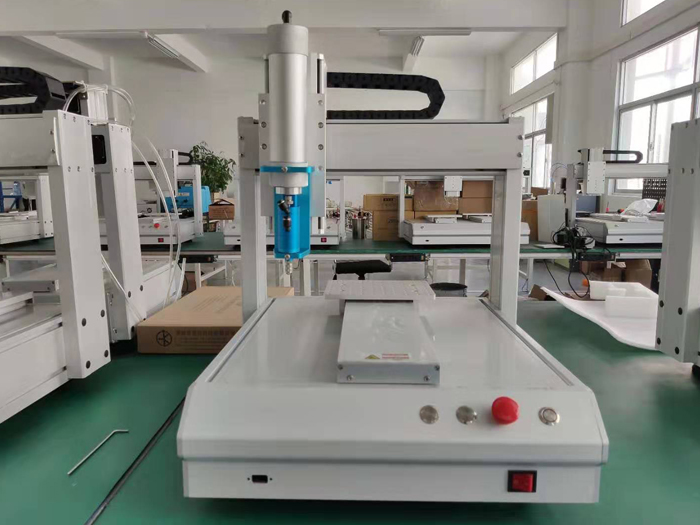

Functional requirements of dispenser

In this process, the performance and compatibility of the point gluing machine are required to be high. In addition to meeting the built-in ratio of two-component compound, it should also be suitable for the characteristics of instant drying of glue for product bonding. Therefore, the configuration of dispensing valve or dispensing process need to be compatible with the application of two-component instant glue before it can be used normally. The bonding strength of PP plastic depends on the stability and uniformity of the glue. Why does instant adhesive need to be made into two-component adhesive? The main reason is that the curing time of single instant adhesive is too fast and there is no suitable adjustment time. Therefore, it is necessary to make two-component adhesive to complete the bonding work normally.

Operation control dispenser

The key is to control the filling compound reasonably and stably. It does not need too thick filling glue, only needs to be even, and the two sides of PP plastic after pressing have relatively high fixation strength.