Imperfect Sealing of Parts Affects the Quality of Product Di

作者:点胶机厂家 日期:2019-03-14 14:30 浏览:

The parts of dispensing machine should be of good quality and strong sealing to ensure stability. If the sealing of the application parts is not good or bad, the products will be directly fed back to the common problems such as the rubber cylinder does not leave glue or the rubber cylinder leaks glue. Some of them are reflected in the use effect of the plastic dispensing needle. The manufacturer of the medium-sized Shenzhen dispensing machine here reminds you that the sealing effect of the parts should be checked. Reason is closely related to the effect of improving the quality rate of dispensing glue.

Composition Structure of Stainless Steel Pressure Barrel

Influences of bad sealing

The bad sealing effect of many parts used for dispensing is embodied in the usage. The needle and needle with good sealing quality can be used steadily for a long time, the output of glue is uniform and the problem of affecting efficiency is not easy to occur. On the contrary, the bad sealing directly leads to the leakage of glue, which is criticized not only for the influence of the quantity of glue transported, but also for the influence of the rate of good products. Poor parts are difficult to be used stably in production lines with high precision requirements, such as motherboard dispensing and other industries with high precision in Shenzhen dispensing machine manufacturing. When purchasing dispensing syringe or common plastic dispensing needle, we should carefully check the effect of the workmanship seal. Both of them are one of the reasons that affect the quality of the motherboard dispensing glue. But the lack of glue in the dispensing syringe is not the main reason.

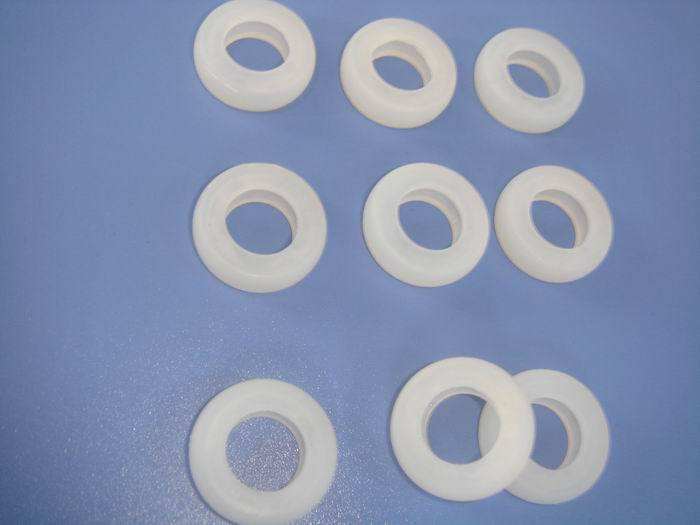

Translucent Silica Gel Seal Ring

Causes slow gum production and gum leakage

There are essential differences between rubber cylinder and rubber cylinder leakage, and the reasons leading to rubber cylinder leakage can be divided into two situations. One is that the rubber cylinder does not emit glue because of the influence of rubber leakage. The common reason is that the slow flow of high-viscosity glue causes partial curing at the rubber outlet of the syringe to block, and the other is that foreign matter blockage at the end of the plastic dispensing needle causes poor sealing. In the aspect of workmanship, it is necessary to inspect the bad sealing condition, and ensure good stability of products with high precision requirements such as motherboard dispensing. This is a simple suggestion given by Shenzhen dispensing machine manufacturer.

Dispensing valve with micrometer

The main board dispensing link needs to fix the parts on the board with glue. The plastic dispensing needle used for dispensing gum needs to ensure the fine dispensing quantity, which is closely related to the poor sealing. The manufacturer of the medium-sized Shenzhen dispensing machine can provide a number of parts with strong sealing and high application life to help the users to finish dispensing of various products steadily.