Application of Fingerprint Module Filling Fluid Requirement

作者:点胶机厂家 日期:2019-06-26 15:03 浏览:

Fingerprint module is a component of smart phone unlocking. It is divided into optical, capacitive, radio frequency and other reaction blocks according to the recognition mode. Through filling the fingerprint module with rubber, it can be bonded to the circuit board to achieve contactable unlocking. In this link, intelligent visual dispensing robot operation should be selected to meet the needs of accuracy and efficiency. Therefore, visual observation points are recommended. As an application control equipment, the glue dispensing valve is controlled by visual positioning function to evenly dispense and fill. The fingerprint module is specially used for filling single component epoxy adhesive, which has good applicability, and is applied to PTC bonding with the same requirements to ensure the quality and efficiency requirements meet the standards.

Filling compound for fingerprint module

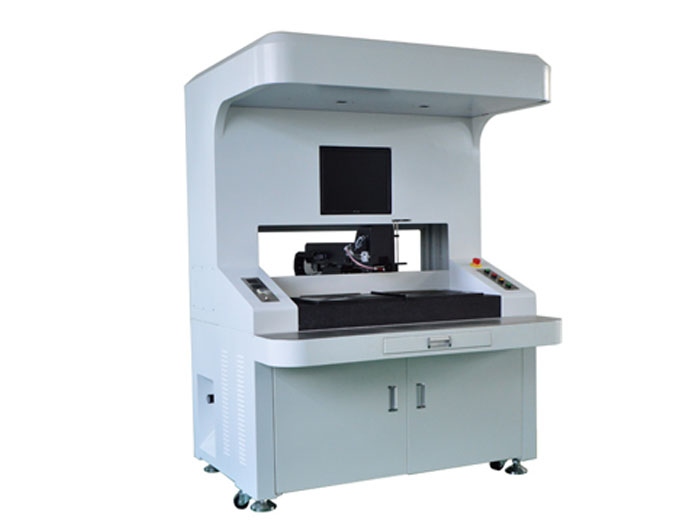

Application of Intelligent Observational Visual Dispensing Robot

The omni-directional recognition function of visual observation dispenser can perform precise control of glue filling and other industrial applications without special fixture fixtures. The dispensing speed, time and height should be adjusted according to the needs of fingerprint module filling. Relatively speaking, the pattern of visual system aided observation and adjustment has a high fault tolerance rate and can be applied to a wide range of filling, so it is equally necessary to finish the dispensing. The finished PTC bonding can also be carried out with this device. As for the selection of fluid dispensing valves, it is recommended to use one-component dispensing valves suitable for epoxy glue. Since the adhesion of fingerprint modules is generally achieved by coating one-component epoxy glue, the selected fluid dispensing valves should meet the actual needs of fingerprint modules for category selection. The filling process of fingerprint modules is briefly introduced below.

Automatic visual observation dispensing robot

Executing the specific process of filling compound

The fingerprint module is placed on the platform of the observation dispensing machine --- parts encapsulation (dispensing of components and driving chips) - - chip bottom filling (dispensing of main chips) - - adhesive solidification --- silver paste (grounding conduction) - - epoxy resin (fixed metal bracket) - - metal fixing ring --- fixing --- pressure holding solidification.

Single-liquid epoxy resin filler

The durable effect of filling compound is stronger

After filling the fingerprint module with appropriate amount of epoxy resin, the effect of the coating material can effectively reduce the overall temperature expansion mismatch between silicon chip and substrate or the impact caused by external forces. From the current situation, the stability of the fingerprint module filled with rubber will be strengthened and the application effect will be stronger. The visual system of the observation dispenser carries a precise control of fluid dispensing valve to control the accuracy of bottom filling. In order to meet the bonding quality, the fingerprint module filled with rubber has good flexibility and maintainability, and can also be used in PTC bonding.