Selection of equipment according to different types of hot m

作者:点胶机厂家 日期:2019-07-24 11:39 浏览:

In order to ensure the bonding effect of environmental protection and safety in production, hot melt pressure sensitive adhesives will be applied to the semi-finished products in an appropriate amount, mainly focusing on the application industries such as cloth bonding and shoe material bonding, etc. The effects of safety and environmental protection can be achieved by proper amount of adhesive coating. In fact, different types of adhesives can be selected according to the different needs of the coating. The equipment is used for gluing, and the mainstream is the automatic operation of PUR hot melt dispenser. In some applications with low demand, manual scraper will be chosen as the automatic equipment to control hot melt glue coating and bonding.

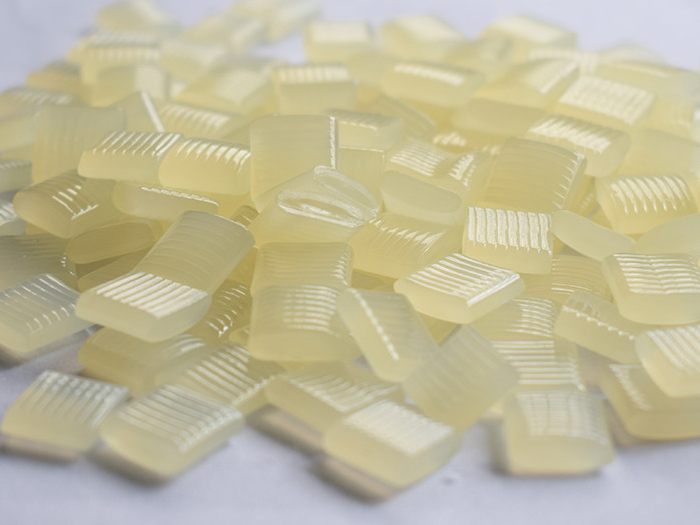

Block Hot Melt Adhesive

Application Degree of Automation Equipment

Hot melt pressure sensitive adhesives are a kind of substance between viscous liquid and elastic solid. When the content of softener is more, they are viscous liquid. They are easy to wet the surface of the adhesives and achieve good initial adhesion effect. Because of the decrease of modulus and viscosity, the irreversible viscous deformation increases and cohesion decreases. The adhesive holdup decreases and can be stored and controlled to the fluid by an automatic PUR hot melt dispenser for coating. This kind of adhesive is environmentally friendly and safe, which meets the needs of clothing industry for cloth bonding or shoe bonding and other applications of hot melt pressure sensitive adhesive.

In fact, in most industries which need hot melt pressure sensitive adhesive coating, the control application of automatic equipment is more preferred. The automatic control mode has high precision of coating and can ensure long-term efficiency and stability, ensure uniform coating of adhesive and increase production at the same time. Therefore, the automatic PUR hot melt dispenser can be selected as the coating agent. With equipment and control system, the semi-finished product can be stably fixed at the work station to control the precise glue discharge. It has the characteristics of easy programming operation and diversified control. Compared with manual scraper, the operation is simple and easy to control.

Fully automatic PUR hot melt dispenser

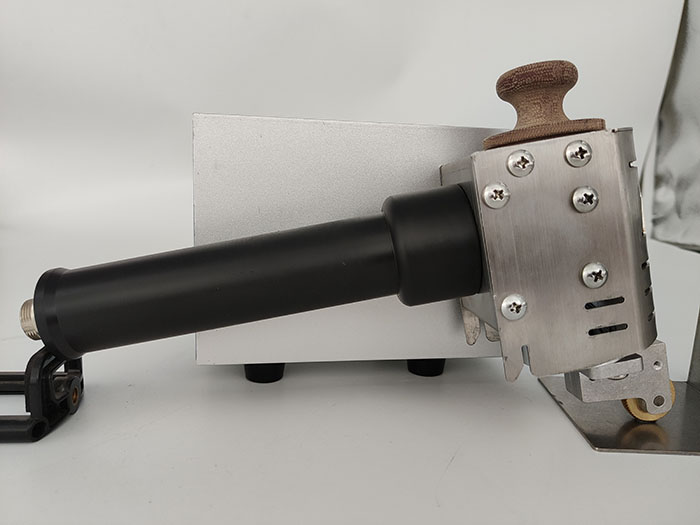

Application of Semi-automatic Handheld Device

In order to achieve a stable scraping path, the traders who need to apply hot melt pressure sensitive adhesive need to apply strip hot melt adhesive at the bonding position to achieve the bonding effect. In fact, the special type of tapping head installed at the bottom of PUR hot melt dispenser can achieve good scraping effect, and the occasion of manual scraper can also be used to control the scraping effect. The hot melt pressure sensitive adhesive is used for path coating. The solid rubber can be heated to the melting state after putting it in the heating position for a period of time. The rubber can reach the effect of strip shape through the bottom pulley. The real-time operation of the manual scraper determines the accuracy and coating stability, which is superior to the automatic PUR hot melt adhesive point. Advantage of hot melt pressure sensitive glue coating by glue machine control.

Semi-automatic Hot Melt Rubber Scraper

Hot melt pressure sensitive adhesives are recommended as adhesives to meet the needs of industry applications.