Eight ways to solve glue drawing

作者:周周 日期:2019-11-07 09:26 浏览:

According to the technical requirements for dispensing in the industry, some products must use high viscosity glue. Under normal circumstances, it is difficult to spray out high viscosity glue with weak fluidity or almost no fluidity, which is suitable for LED tubes, chips, etc. the automatic dispensing machine has high viscosity glue for dispensing, sometimes there is drawing phenomenon, which affects the dispensing quality and aesthetics. Then how to solve the drawing problem What about it?

Solution:

1. Glue delay

When starting the machine for dispensing, due to the distance between the glue outlet and the glue valve, it takes time for glue delivery. If dispensing is carried out immediately and moving the track at the same time, there will be no glue at the beginning of the product. In order to prevent this situation, after opening the glue, delay for a period of time, wait for the glue to flow out, and then perform dispensing action. This method is called delayed dispensing.

2. Glue closing delay

After the rubber head is closed, there is still glue between the rubber head outlet and the rubber valve. If it moves immediately after the rubber head is closed, it may form the phenomenon of glue tail. In order to prevent this situation, after the rubber head is closed, wait for the glue to flow out for a period of time, and then carry out subsequent operations. This delay time is called glue closing delay.

3. Breaking height

Due to the high viscosity of some glues, the glues will break only when they are slowly raised at a constant speed for a certain distance without affecting the gluing track, which is called the breaking height.

4. Lifting height

After dispensing, when a section of track moves to the starting point of the next section of track, in order to prevent the rubber head from hitting the needle, the rubber head is lifted to a certain height at the end point to ensure that the rubber head moves to the starting point of the next section of track safely without hitting the needle, which is called lifting height.

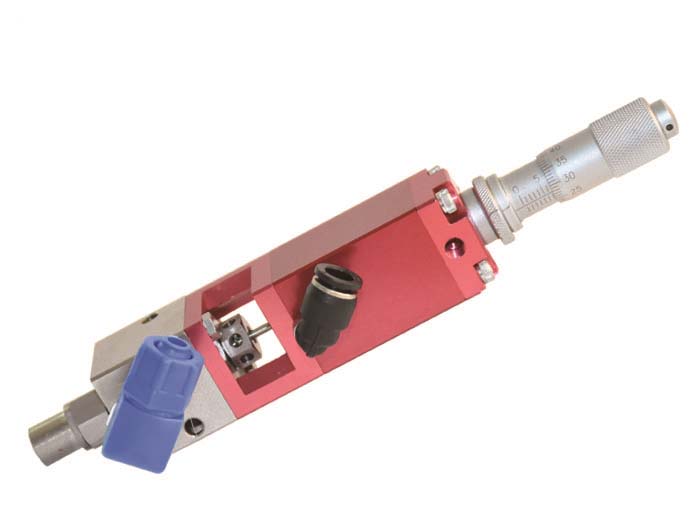

Thimble type control glue dispensing valve

5. Close the glue in advance

Closing glue in advance refers to closing glue before the end of a certain distance, i.e. in continuous track gluing, closing glue in advance before reaching the end point, completing the last track with residual pressure and glue to avoid the end of glue accumulation.

6. End action

After the glue coating of the whole track is completed, in order to facilitate the pick-up and placement of the workpiece, improve the processing efficiency or eliminate the processing error, the user can move the rubber head to the designated position, which can be the starting point of the processing document or the end point of the processing document or make the reset action, which is the glue closing action.

Micrometer precision dispensing valve

7. Diagonal pull up

As the glue is sticky, the z-axis height can not be lifted directly to break the glue, which is easy to lead to wire drawing problems. Therefore, after the rubber head is closed, perform the diagonal pull-up action to prevent wire drawing problems.

8. Glue heating

You can try to heat the glue to a suitable temperature, increase the fluidity of the glue, in a sense, you can also solve the problem of wire drawing! Pay attention to the heating temperature is not too high!