Sensitivity test method of visual dispensing machine

作者:周周 日期:2019-11-11 09:11 浏览:

The accuracy and reliability of the detector depend on the stability of the frequency of the electromagnetic transmitter. Generally, the working frequency of 80-800 kHz is used. The lower the working frequency is, the better the detection performance is. Vice versa. The sensitivity of the detector will decrease with the increase of the detection range. The size of the induced signal depends on the size and conductivity of the metal particles. The reason for this is that the current pulsation and the filtering effect are weakened The full-automatic detector has a certain limit on the conveying speed of the detected objects. If the conveying speed exceeds a reasonable range, the sensitivity detection of the machine will be reduced.

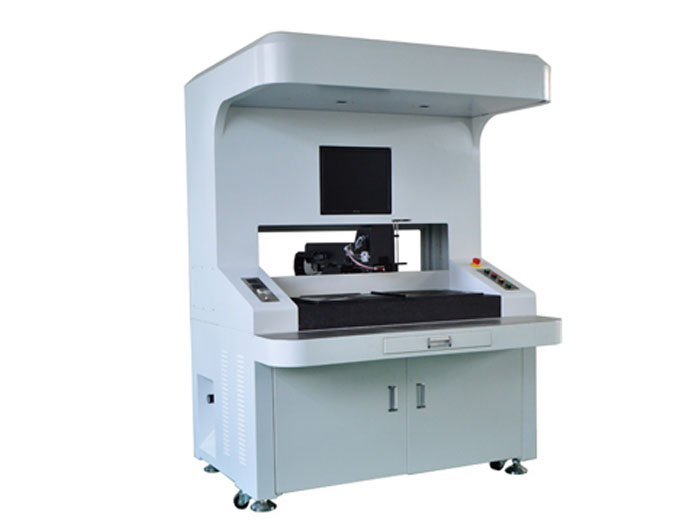

Floor type visual dispensing machine

Advantages of sensitivity of Chinese visual dispensing machine

1. High resolution image, color combined light source and 2D (3D) algorithm are used in chip and lead detection system to detect lead frame, which solves the defect that chip and lead are too small to detect.

2. High precision, high speed, stability, positioning, controllability and other characteristics;

3. Defect identification and classification technology is designed inside the machine, which is applicable to lead wires of various materials.

4. It can detect the chip surface, edge, foreign matters, scratches and glue.

5. The false inspection rate is less than 1%, the missed inspection rate is less than 0.5%, and the production capacity is ≥ 10K pieces / hour.

Desktop visual dispensing machine

In order to ensure that the sensitivity will not drop, some products can be selected for the sensitivity test of the visual dispenser. Generally speaking, the detection range should be controlled at the minimum value as far as possible. For products with good high frequency induction, the channel size of the detector should match the product size. The adjustment of detection sensitivity should be determined by referring to the center of the detection coil. The center induction is the lowest The product detection value will change with the change of production conditions, such as the change of temperature, product size, humidity, etc., which can be adjusted and compensated by the control function.