Summarize the inspection method of dispensing quality of fiv

作者:点胶机厂家 日期:2019-12-03 09:57 浏览:

The automatic visual dispensing machine is specifically used in the bonding, pouring, coating, sealing and other technologies of semiconductor, electronic parts and LCD products. The dispensing quality inspection of products is the key target to be inspected in dispensing. The usual inspection methods include knocking method, visual inspection method, acoustic resistance method, ultrasonic method, pressurization method, etc.

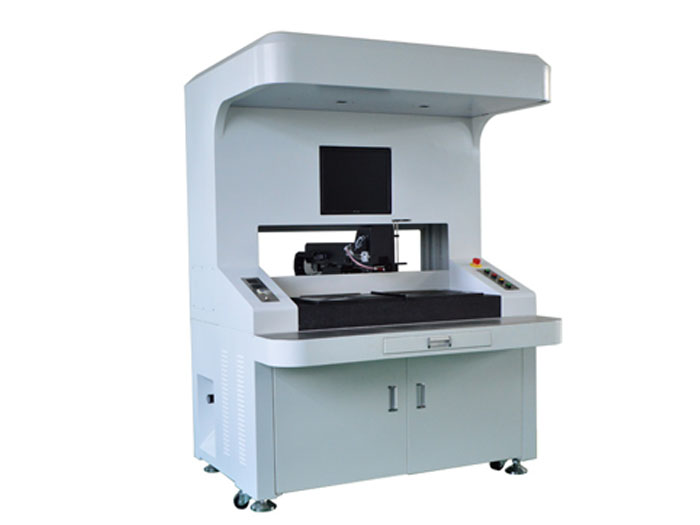

Automatic vision matching dispensing system

The quality inspection method of automatic visual dispensing machine:

1. Knocking method: knock the bonding surface with a small hand hammer, and check the dispensing quality with the sound from it. If the sound from percussion is clear, it indicates that there is no defect locally; on the contrary, if the sound from percussion is dull, it indicates that there are defects and bubbles inside.

2. Visual inspection: the inspector shall use his eyes to observe the interface of the adhesive parts and check whether there are cracks, cracks and glue shortage.

Floor type visual dispensing system

3. Acoustic resistance method: in view of the different bonding quality and vibration impedance of the test piece, the resistance variation of the bonding interface equipment can be analyzed according to the acoustic resistance detector. If the measured impedance is significantly reduced, it indicates that the bonding has shortcomings.

4. Ultrasonic method: the ultrasonic wave used for flaw detection is transferred to the order of 1o6. If there are defects in the bonding interface during the dispensing quality inspection, the ultrasonic wave can reflect such defects back, and then check whether there are bubbles, defects or degumming in the adhesive layer.

5. Pressurization method: compared with the sealed and pressurized adhesive parts, the pressure sealing test can be carried out according to the task solvent and pressure. If there is no leakage during the dispensing quality inspection, it indicates that there is no defect. It is a qualified product.

Adjustable industrial lens

The above information is about the dispensing quality inspection method of the full-automatic visual dispensing machine. Presumably, you have a certain understanding that the quality of the glue has a great interference on the final dispensing function of the product. Therefore, you need to recognize the quality inspection method of the adhesive to ensure that the product quality reaches the standard.