New intelligent vision dispensing robot observation model

作者:点胶机厂家 日期:2019-06-25 15:00 浏览:

The function of visual dispensing equipment is far superior to that of conventional desktop dispensing machine. An intelligent visual dispensing robot will perform more efficiently. Therefore, visual observation dispensing machine has outstanding advantages such as high accuracy, good quality and fast recognition by combining visual inspection system with fluid dispensing valve. The product can recognize glue without fixing a special work station, and can be applied in demand precision control. In the links of PTC bonding and fingerprint module filling for visual reasons, the technical parameters of this observable visual dispenser will be briefly introduced below.

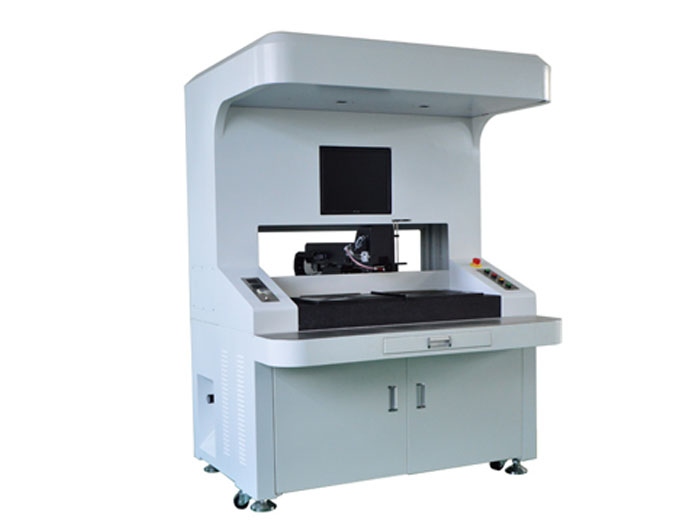

Automatic visual observation dispensing robot

Technical parameters of equipment

Product Name: Automatic Visual Observation Dispenser Model: ZZ-SJ03

Operating System: PC Motion Control Card Speed: 350Mm/sec

Driving mode: Stepping motor + screw drive accuracy: +0.01mm

Display Mode: PC Video Display Camera: High Definition 500W Pixels

Suitable rubber valves: single or double component fluid dispensing valves

Industry Applications: Watch Filling, Fingerprint Module Filling, PTC Bonding, Mobile Chip Coating

Automatic visual dispensing robot

Overall introduction of equipment

Intelligent visual observation dispensing machine is equipped with PC display screen to facilitate observation and adjustment of parameters. WINDOWS Chinese operating interface is adopted. The omnidirectional recognition of visual observation function can be used for precise control of adhesive filling and other industrial applications without special fixture fixtures. The dispensing speed, time and height can be adjusted. It can be used for linear, wavy and cross-gluing. Manipulating two machines by one person plays an important role in saving labor. At the same time, the equipment failure rate of this dispensing machine is low and the stability is stronger. It is more suitable for filling fingerprint module after PTC bonding.

In the manufacture of fingerprint module, due to the need for appropriate amount of rubber coating to the bottom, the effect of the coating can effectively reduce the overall temperature expansion characteristics mismatch between the silicon chip and the substrate or the impact caused by external forces. On the whole, the life of the fingerprint module after filling will be improved and the application effect will be better. The observation dispenser carries a visual system to precisely control the fluid dispensing valve to control the bottom filling. The precision effect is in line with the required accuracy. The fingerprint module after gluing has good flexibility and maintainability.

Fingerprint Module Coating Spot Glue

Various types of fluid dispensing valves can be selected to control the dispensing machine. Visual inspection dispensing can be carried out with single component or double component dispensing valves. Pressure barrel storage can also be carried out, which can save more time for changing glue.